Drive Train

-

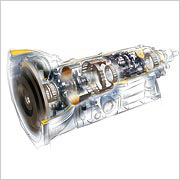

Automatic Transmission

Automatic transmissions ensure smooth gear changes with minimal shift shock while operating under various kinds of driving conditions. A complex and extremely intricate form of technology known as friction control is ideal for efficiently conveying power from the engine and for smooth gear shifting. Friction-related parts and one-way clutches, which have been developed based on our advanced tribology technology, are the most important products in determining the performance of automatic transmissions. They contribute to a smooth and powerful driving experience.

-

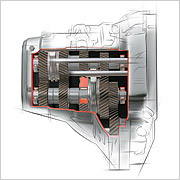

Manual Transmission

Manual transmissions must adequately meet driver expectations of control by conveying a smooth, precise, and crisp feeling. Transmissions must also be compact, lightweight, and be able to deliver excellent fuel efficiency for the increased number of gears that are appearing in newer vehicles. The bearings and synchronized parts created by NSK play a key role in supporting the future of manual transmissions with their unsurpassed reliability and capability developed with tribology technology.

-

Motorcycles & All-Terrain Vehicles

NSK's products are also used in a wide variety of vehicles ranging from motorcycles to all-terrain vehicles. The mechanical parts of motorcycles are exposed to rough running and high-rotation conditions, while all-terrain vehicles are utilized in a vast range of activities and environmental conditions. Bearings for these vehicles must be durable against water and mud. To meet these requirements, NSK offers highly durable, well-sealed bearings. NSK has put a great deal of effort in to developing unitized products to enhance usability.

-

Half Toroidal CVT POWERTOROS Unit

The Half Toroidal CVT is an innovative transmission that executes smooth, continuous gear ratio changes by changing the angle of the power rollers between the input disk and output disk. Toroidal CVT development began in 1877. One hundred years later, NSK undertook its development in 1978, spending as much as 21 years to develop a practical application. Featuring smooth, silent, and continuous gear ratio changes, as well contributing to conserving energy and further reduction of CO2 emissions, the highly efficient Half Toroidal CVT POWERTOROS Unit is the desired transmission that is a result of NSK's advanced technology in tribology.

-

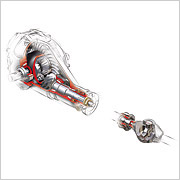

Differential Gear & Propeller Shaft

In FR vehicles, the engine power is transmitted to the rear differential gear via the propeller shaft. The fact that the center bearing used to support the propeller shaft is located on the vehicle's exterior gives rise to a demand for optimum mud and turbid water resistance in addition to maintaining fast rotational speeds. Due to the large speed-reduction gear ratio of the rear differential gear that conveys engine power to the rear wheels, a large gear-interlocking load affects the bearings that provide support for the pinion gear and the ring gear. In particular, bearings that support the pinion gear require low torque and high durability since these bearings rotate at the same speed as the propeller shaft.